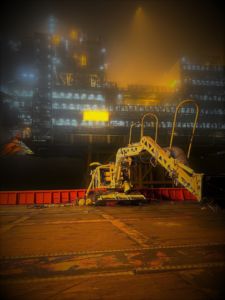

Scanmudring, a leader in subsea excavation and dredging services, recently approached us with a request to upgrade their 20Te excavator’s subsea pressure housing for use at greater depths. After several years of use, the housings needed to be verified for use at a depth of 3000 meters.

We revisited the calculations and pressure testing and worked with Scanmudring to find a solution. We decided to fit new flanges and lids made of titanium to the existing composite tubes. The new housings were then tested to a depth of 3300 meters to ensure their safety and reliability.

The new lids had the added benefit of being lighter in weight, making them easier to handle and move. Additionally, all the connectors were consolidated onto one lid, streamlining the design and improving the housing’s overall efficiency.

We were able to engineer and manufacture the upgrades quickly, minimizing downtime and allowing Scanmudring to get back to work as soon as possible. Regular inspection and maintenance of subsea equipment are critical for ensuring safe and reliable operation, and we were proud to help Scanmudring upgrade their pressure housing to meet their needs.

Would you like to know more about what kind of products we can help you develop? Feel free to contact us: office@windtec.no