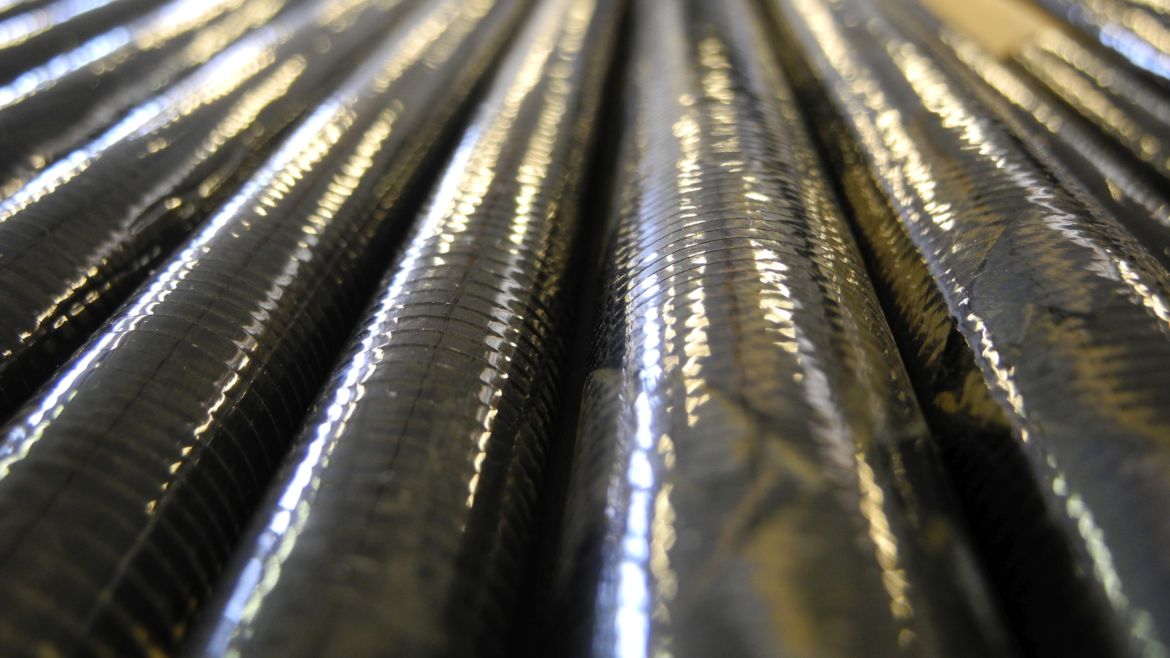

Filament wound composite tubes have excellent stiffness and strength. The winding process places the fibers continuously around the tube at predefined angles and with tension to get accurate placement. Low winding angles are used for axial stiffness and higher angles are used for pressure and torsion applications.

Filament wound tubes are used in light weight frames, UAVs, robot arms, shafts, motor sports, spinnaker booms, SUP oars and kayak paddles and many more.

The tubes are custom made with material and layup tailored to your application. Available sizes are from 12 mm diameter and up and up to 1200 mm length, but we can produce tubes up to 2 meter in diameter or 4 meters in length.

The fibers we use are prepreg with epoxy resin and we stock material with standard modulus carbon fiber (Toray T700 or similar), S-glass and aramid fibers. The epoxy resin has a temperature resistance of 100 degrees C, but special resins are also available on request.

Windtec can deliver tubes with an unsanded, sanded or painted finish.